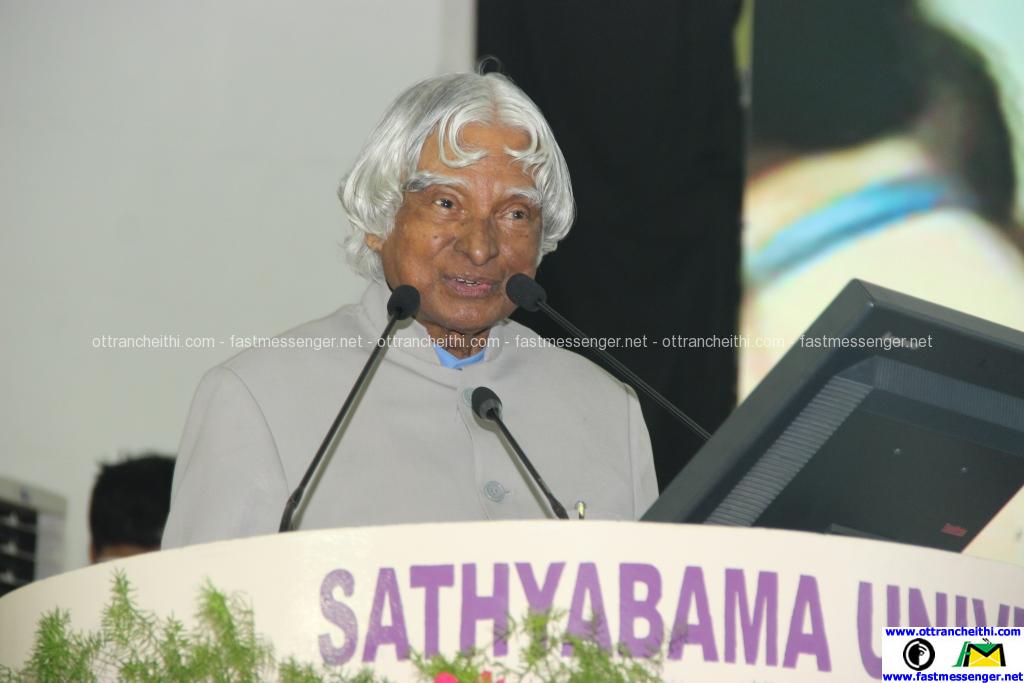

The Centre of Excellence for Energy Research funded by the Ministry of Human Resource Development (MHRD), Govt. of India was inaugurated by His Excellency Dr. A. P. J. Abdul Kalam, Former President of India at 3 PM on December 9th, 2014 in the august presence of Col. Dr. Jeppiaar, Founder and Chancellor of the Sathyabama University.

The generation of energy and storage of energy in useful form with eco-friendly manner is now one of the major challenges for scientists and engineers throughout the world. The Centre of Excellence for Energy Research at Sathyabama University aims to enhance the quality and quantity of basic and applied research programs in energy studies. The Centre also would organize training programs/workshops/conferences for students, researchers, academic staff, and scientists in India to further strengthen their expertise in the areas of energy research, to accelerate the India’s human development index and to provide energy security. This centre would contribute significantly in building a robust research centre for energy to carry out R&D programmes in the areas of Solar Cell, Solar Thermal, Fuel Cell, Bio-energy and Super capacitors etc.

The Centre of Excellence for Energy Research focuses on improving the conversion efficiencies of the solar cell using low cost solar energy absorber materials. Copper-Zinc-Tin-Sulphide (CZTS)-based thin-film solar cell modules currently represent one of the fastest-growing segments of commercial module production due to the presence of the earth abundant materials. The synthesized CZTS materials will be used to fabricate CZTS thin films to achieve high efficiency photovoltaic modules. In addition, development of high-temperature solar-selective coatings for solar thermal applications using multiple cermet layers by physical vapor deposition (PVD) will be undertaken to develop new, more-efficient selective coatings with both high solar absorptance and low thermal emittance that are thermally stable above 500ºC, ideally in air, with improved durability and manufacturability and reduced cost.

The fuel cells are devices which convert fuel (H2) and air (O2) into electricity and heat. The fuel cells can be easy rechargeable, have high energy density, and do not produce greenhouse gases. The fuel cell consists of three major components, namely, anode, cathode and electrolyte or ionic conductor. The centre aims to develop advanced electrolytes for Solid Oxide Fuel Cell (SOFC) and Proton Exchange Membrane (PEM) Fuel Cell. Gadolinia and Samaria doped ceria which show higher ionic conductivity than YSZ in the low temperature regime will be developed as an electrolyte for SOFC by pulsed laser deposition. The calix[n]arene based polymeric materials (here n= 4,6 and 8) are considered for Proton Exchange Membrane Fuel Cell to improve the humidification of the membrane, increase the current density, reduce the electro-osmotic drag, suppress fuel cross-over, improve mechanical strength, improve thermal stability and enhance the proton conductivity.

Vitrification of high level nuclear waste (HLW) is considered to be one of the important immobilization options today. This is being carried out in a vitrification furnace made up of a super alloy. However, the components of the vitrification furnace have been reported to degrade prematurely due to molten glass-alloy interactions at high temperatures and thereby increase the volume of the metallic nuclear waste. Application of compositionally graded coatings (CGC) on Ni- base super alloy has been recommended to reduce faster degradation or premature failure of components of the vitrification furnace or melter pot made up of Ni-base super alloy. The use of CGC has the potential to simultaneously reduce thermal expansion mismatch, increase interface bonding strength, and enhance coating toughness. In order to reduce the waste inventory of radioactive materials, compositionally graded Ni-YSZ composite coatings on Ni base super alloy by electron beam evaporation will be developed.

The development of nano-science can have a great impact in the field of civil construction materials used in nuclear installations. Better understanding and engineering of complex structure of cement based materials at nano-level will definitely result in a new generation of concrete, stronger and more durable, with desired stress-strain behaviour and possibly with the whole range of newly introduced smart properties. With a high quality or an impermeable concrete skin, the chemical and biological attack by seawater can be limited. For instance, experimental research in partial replacement of Portland cement with appropriate pozzollans such as fly ash is in progress. This approach could densify the matrix and make the concrete impermeable.

Quantum dots have tunable band gaps across a wide range of energy levels by merely changing the size of the dots. In the case of bulk materials, the band gap is fixed by the choice of material. CdTe or CdSe quantum dots based solar cells can replace conventionally used bulk materials. The size tunability of quantum dots makes them potential candidates for fabricating multi-junction solar cells. Graphene based nanomaterial’s exhibit high mechanical flexibility, large surface area, chemical stability, superior electric and thermal conductivities. They can be used for enhancing the energy capacity and charging rate in rechargeable batteries and as super capacitors for energy storage.

A stringent environmental regulation has led to the development of several non-conventional and alternate technologies. Like the many upcoming technologies, bio-energy is competent in both sustainability and economy. Research in the production of Biodiesel, Bioethanol and Bio hydrogen will be carried out by studying their performance in engines (Biodiesel & Bioethanol) and fuel cells (Bio hydrogen) to commercialize the proposed processes. Emissions from engines after replacement of conventional fuels with alternate fuels will also be analysed to establish climate change models. Additionally, waste heat harvesting and microbial anaerobic digestion of waste water for electricity production are also being carryout as a recovery measure.